Cornwall stone is a well-known material used in ceramics, particularly in glaze recipes, due to its high feldspar content and unique mineral composition. The traditional Cornwall stone glaze recipe produces a creamy, semi-transparent finish with a soft, speckled appearance that potters and ceramicists often seek for their work. This mineral has been a staple in creating both matte and glossy finishes, with a hint of a satin texture that gives pottery an earthy, organic appeal.

In this guide, we’ll explore how to craft the perfect Cornwall stone glaze recipe, providing expert advice and insights. From understanding the raw materials involved to adjusting the recipe for different firing temperatures, we’ll cover it all. If you’re looking to create a reliable glaze with Cornwall stone, this guide is your go-to resource.

What is Cornwall Stone?

Cornwall stone, also known as Cornish stone, is a feldspathic material primarily composed of potash feldspar, quartz, and mica. It originates from Cornwall, UK, and has been used in ceramics for centuries. This stone provides an essential ingredient in glazes due to its balanced silica and alumina content, which helps in achieving a stable glaze fit and unique surface finish.

Key Properties of Cornwall Stone in Glazes

- High feldspar content: Provides fluidity and fluxing in the glaze during firing.

- Natural speckling and variegation: Adds character to the glaze, giving each piece a unique finish.

- Versatility: Suitable for both high-temperature and low-temperature glaze applications.

How to Make a Cornwall Stone Glaze Recipe

To create a Cornwall stone glaze, you typically combine it with other essential glaze materials like silica, kaolin, and fluxes. The following recipe is a foundational blend that can be adjusted based on your preferences:

Basic Cornwall Stone Glaze Recipe:

- 70% Cornwall stone

- 15% Silica

- 10% Kaolin (EPK)

- 5% Whiting

This recipe is ideal for cone 10 reduction firings, but it can be modified for lower temperatures or different firing environments.

Adjusting the Recipe for Different Firing Ranges

- For cone 6: Decrease the amount of Cornwall stone to around 60%, increase kaolin to 15%, and consider adding 5% talc to improve melt.

- For cone 04-06 (low fire): Replace a portion of Cornwall stone with frits like Ferro 3134 or 3124, which promote a smooth melt at lower temperatures.

Testing and Refining Your Glaze

Every kiln and clay body can influence the final outcome, so it’s essential to conduct test tiles. Experiment with varying amounts of each component to tweak the texture, gloss level, and color of your glaze. Keep detailed records of your results to track what works best for your specific conditions.

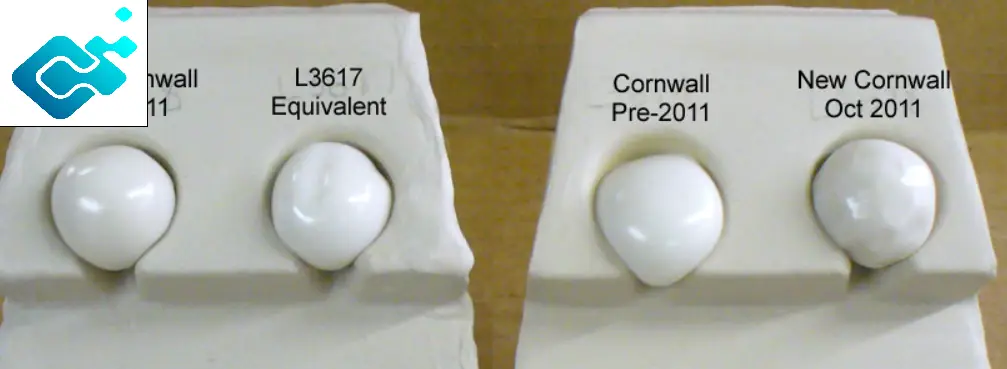

Substituting Cornwall Stone in Glaze Recipes

If you can’t source Cornwall stone, there are alternatives like Nepheline Syenite, Kona F-4 feldspar, or G-200 feldspar that can produce similar results. However, these substitutions often require additional adjustments to maintain the glaze’s stability and desired finish.

Using Nepheline Syenite as a Substitute

Nepheline syenite is a feldspathic rock with similar properties but slightly higher in flux content, making it a good replacement. When using it, reduce the kaolin content to balance out the increased flux.

Common Issues with Cornwall Stone Glazes and How to Fix Them

Even experienced potters encounter issues when using Cornwall stone. Common problems include crazing, pinholing, and uneven gloss. Here’s how to address these challenges:

Crazing

Crazing occurs when the glaze contracts more than the clay body. To fix it, increase the silica content or adjust the alumina levels by adding more kaolin.

Pinholing

Pinholing, often caused by trapped gases during firing, can be minimized by a slower firing schedule or adding bentonite to the recipe.

Frequently Asked Questions (FAQs)

Is Cornwall Stone Still Available for Purchase?

Yes, Cornwall stone is still available, though it is becoming less common as quarries deplete. Many ceramic suppliers stock it or offer similar alternatives.

Can I Use Cornwall Stone Alone as a Glaze?

No, Cornwall stone alone doesn’t create a functional glaze. It needs to be combined with silica, kaolin, and other fluxes to produce a balanced glaze.

What Type of Clay Body Works Best with Cornwall Stone Glazes?

Cornwall stone glazes work beautifully on porcelain and stoneware bodies, especially in reduction firings, due to the mineral’s high feldspar content.

Conclusion

Creating the perfect Cornwall stone glaze recipe involves understanding the material’s properties and adjusting the recipe to match your firing range and desired finish. By experimenting with different proportions and firing schedules, you can achieve stunning, timeless pottery glazes. Whether you’re a beginner or a seasoned potter, Cornwall stone remains a valuable and versatile material in glaze formulation.

With this guide, you now have the essential knowledge and expert tips needed to craft a beautiful glaze using Cornwall stone. Happy glazing!